History & Development

In 2008, as diesel fuel prices started to rise from $3.00 to over $4.75 per gallon, Lester Erlston and Mike Miles were developing a retrofit conversion to hybridize diesel city buses and garbage trucks, to reduce fuel consumption. There are two basic approaches to hybridize a diesel vehicle to recover and reuse brake energy: either by adding an electric motor or a hydraulic motor into the vehicle’s drivetrain. However, electric motors maximize their energy efficiency at higher motor speeds, while hydraulic motors maximize efficiency at lower RPMs.

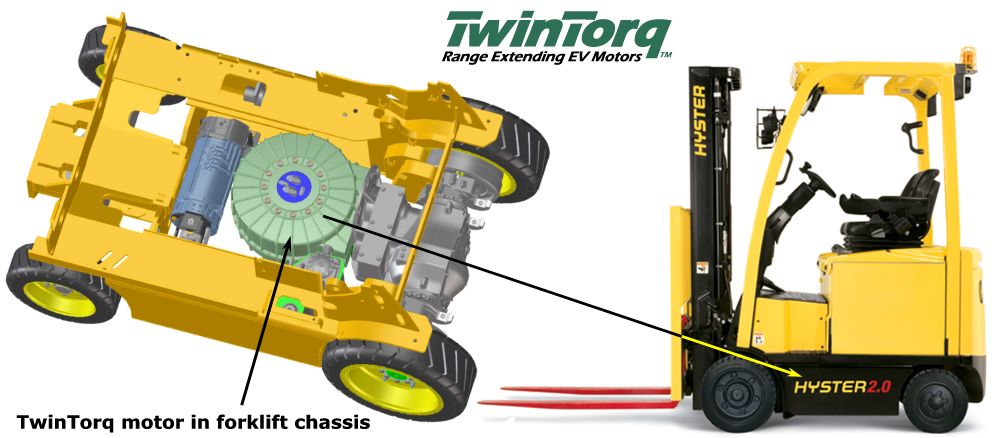

What intrigued Lester and Mike was, could an electric motor and a hydraulic motor be combined into a single motor to maximize energy efficiency across the entire motor speed range? The result was the invention of TwinTorq, the first combined electric-hydraulic motor for electric vehicles, that offers more battery driving range and longer battery life than any other electric vehicle motor. Such a technology leap compared to existing solutions generally causes disruption in well established markets.

Anticipating the global potential for the TwinTorq motor, particularly for commercial electric vehicles, the inventors formed KersTech, based in Portland, Oregon, a fast-growing hub of electric transportation development, to design, develop and manufacture applications of the motor for a broad range of vehicle markets.

Forklifts were selected as KersTech’s first application because this market has adopted electrification at a faster rate than any other vehicle, with over 65% of forklift sales now electric. Local investors and institutions have funded a first prototype motor and its control software designed for a midsize electric forklift, which is now being extensively tested at the Oregon R&D facility of a world leading forklift manufacturer.